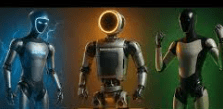

As the sun rises over this crisp morning at 08:16 AM MST on Sunday, September 28, 2025, let’s take a moment to marvel at the technological marvels shaping our world. Inspired by the fictional Skynet from the Terminator series—an AI that pushed boundaries and sparked imagination—we turn our gaze to three remarkable humanoid robots: China’s Unitree G1, Boston Dynamics’ Atlas, and Tesla’s Optimus. These machines are not harbingers of doom but symbols of human ingenuity, each offering a unique glimpse into a future where robotics and artificial intelligence (AI) collaborate with us. The G1, launched in 2024 and refined throughout 2025, brings robotics to the masses with an approachable $16,000 price tag, making it a household name in accessibility. Atlas, reimagined with an all-electric design in 2024 and enhanced in 2025 through a partnership with Toyota Research Institute, showcases unparalleled athleticism and industrial potential. Meanwhile, Tesla’s Optimus Gen 3, unveiled in 2025, stands tall at 173 cm and weighs 57 kg, with a target price under $30,000 and plans for mass production by the end of this year, positioning it as a versatile companion for homes and factories alike.

These robots are evolving rapidly, integrating advanced AI and undergoing rigorous real-world testing. The G1 focuses on scalability and affordability, Atlas excels in strength and dynamic performance, and Optimus bridges the gap with its adaptability for everyday tasks. This extended exploration delves deep into their creation processes, detailed specifications, diverse capabilities, strengths and weaknesses, and the multifaceted future they promise. Whether you’re a researcher intrigued by affordable prototypes, an engineer envisioning heavy-duty industrial solutions, or a homeowner curious about robotic assistance, this comprehensive analysis offers something for everyone. Let’s embark on this journey together, drawing inspiration from Skynet’s fictional caution as a reminder to guide our innovations responsibly, ensuring a future of collaboration rather than conflict.

The Genesis: Crafting Tomorrow’s Helpers with Precision and Vision

The development of these humanoid robots is a testament to the power of simulation, engineering expertise, and forward-thinking design, each reflecting a distinct approach to building a better tomorrow.

- Unitree G1: The G1’s journey begins in the virtual realm with NVIDIA’s Isaac Simulator, where a “digital twin” is meticulously crafted. This digital counterpart is trained using extensive motion-capture data collected from human movements—everything from walking and climbing stairs to intricate hand gestures—combined with reinforcement learning (RL) algorithms. These algorithms allow the G1 to iterate through millions of virtual scenarios, refining its skills in a safe, controlled environment before transferring them to the physical robot through a process known as Sim2Real. The hardware is assembled in Unitree’s state-of-the-art 10,000-square-meter factory in Hangzhou, China, where vertical integration ensures quality and cost efficiency. The robot’s frame is forged from a lightweight magnesium-aluminum alloy, paired with low-inertia permanent magnet synchronous motors (PMSMs) and crossed roller bearings for smooth, heat-dissipating joint movement. Its sensory suite includes a Livox Mid-360 LiDAR for 360-degree environmental mapping, Intel RealSense D435 depth cameras for precise vision, a four-microphone array for voice command recognition, and inertial measurement units (IMUs) for balance. Powering this system is a 9,000mAh quick-swap lithium battery, controlled by an 8-core CPU (upgradable to NVIDIA Jetson Orin in the EDU variant). The software backbone, Unitree’s UnifoLM (Unified Robot Large Model), integrates imitation learning and force-position hybrid control, enabling dexterous manipulation. In 2025, over-the-air (OTA) updates have further enhanced its capabilities, particularly with the introduction of optional three-fingered hands for tactile tasks, making it a versatile platform for research, education, and light industrial use.

- Boston Dynamics Atlas: Atlas’s origin story is rooted in decades of research funded by DARPA, the U.S. Defense Advanced Research Projects Agency, reflecting a focus on rugged, high-performance robotics. The 2025 electric version marks a significant evolution from its hydraulic predecessors, developed in collaboration with Toyota Research Institute. This iteration employs large behavior models (LBMs) that leverage head-mounted cameras, proprioceptive sensors, and end-to-end reinforcement learning policies to master complex movements. The robot’s training occurs in simulated environments where it learns to navigate obstacles, perform acrobatics, and collaborate with other units, with real-world data refining its skills. Atlas is constructed with titanium-aluminum 3D-printed parts, offering a robust yet lightweight frame capable of withstanding demanding conditions. Its custom electric actuators provide a torque density of 220 Nm/kg, enabling a broad range of motions across its 28 actuated degrees of freedom (with up to 78 total when including passive joints). Equipped with stereo vision, LiDAR, and advanced inertial sensors, Atlas excels in dynamic environments. The 2025 enhancements, including improved battery efficiency and team-based task execution, position it as a leader in industrial and rescue applications, with ongoing pilots demonstrating its potential in construction and logistics.

- Tesla Optimus (Gen 3): Optimus’s development traces back to Tesla’s bold announcement at its 2021 AI Day, where Elon Musk envisioned a robot to accelerate human scientific discovery. By 2025, the Gen 3 model has matured significantly, building on the company’s Full Self-Driving (FSD) AI technology honed in its autonomous vehicles. This robot is trained on vast datasets encompassing household and industrial tasks, using imitation learning and adaptive algorithms to perform actions like folding laundry, watering plants, or serving drinks. The hardware features custom-designed actuators engineered for decade-long reliability, heat-dissipating servos to manage thermal loads, and a total of 40 degrees of freedom—distributed across 6 DoF per arm, 6 DoF per hand, and additional joints for torso and legs—allowing for nuanced and human-like movements. Its sensory system includes high-resolution cameras and ultrasonic sensors derived from Tesla’s automotive tech, providing real-time environmental awareness. Powered by a custom lithium battery pack offering 2-4 hours of operation (depending on task intensity), Optimus is designed for scalability, with Tesla planning to produce millions by 2026 at a price point under $30,000. This focus on mass production and affordability, combined with its ability to learn from human demonstrations, positions Optimus as a potential game-changer for domestic and industrial automation.

These creation processes highlight a synergy of virtual training and physical craftsmanship, each robot evolving to meet specific needs while laying the groundwork for broader societal integration.

Core Specifications: Diverse Designs for Diverse Needs

The physical attributes of G1, Atlas, and Optimus reflect their intended roles, offering a spectrum of options for various applications.

| Feature | Unitree G1 | Boston Dynamics Atlas (Electric 2025) | Tesla Optimus (Gen 3 2025) |

|---|---|---|---|

| Height | 1.32 m (standing); 0.69 m (folded) | ~1.52 m (5 ft) | 1.73 m (5’8″) |

| Weight | ~35 kg | ~89 kg (196 lbs) | ~57 kg (125 lbs) |

| Degrees of Freedom (DoF) | 23 (standard); up to 43 (EDU) | 28 actuated; up to 78 total | 40 (detailed: arms 6×2, hands 6×2, etc.) |

| Speed | Up to 2 m/s (7.2 km/h) | Up to 2.5 m/s (9 km/h) | Up to ~1.4 m/s (improved gait) |

| Payload Capacity | 2-3 kg (arms) | Up to 11 kg (dynamic) | Up to 20 kg (45 lbs) |

| Battery Life | ~2 hours (9,000 mAh Li-ion) | 1-4 hours (task-dependent) | ~2-4 hours (custom pack) |

| Price | $16,000 (consumer/EDU) | Est. $500K+ (prototypes) | Under $30,000 (production 2025) |

| Materials | Magnesium-aluminum alloy | Titanium-aluminum 3D-printed | Custom lightweight composites |

| Sensory Suite | LiDAR, RealSense cameras, 4-mic array, IMUs | Stereo vision, LiDAR, inertial sensors | High-res cameras, ultrasonic sensors |

| Control System | 8-core CPU (upgradable to Jetson Orin) | Custom electric actuators with LBMs | FSD-derived AI with custom actuators |

The G1’s compact, foldable design suits portable applications like educational labs or small homes, while Atlas’s sturdy build is ideal for industrial sites and rugged terrains. Optimus strikes a middle ground, offering a humanoid stature and lightweight frame for seamless integration into daily life, with materials optimized for durability and heat management.

Capabilities: Versatility in Action Across Scenarios

These robots bring a range of skills to the table, each tailored to specific environments and tasks.

- Mobility and Dynamics: The G1 demonstrates impressive agility, performing backflips, martial arts katas, and maintaining balance on uneven surfaces at speeds up to 2 m/s, thanks to its 6 degrees of freedom per leg. Its ability to recover from falls or pushes showcases its stability. Atlas takes mobility to new heights with parkour leaps, 360-degree spins, and collaborative team movements, reaching 2.5 m/s and handling dynamic tasks like construction site navigation. Optimus, with its improving gait, navigates factory floors and home settings, climbing stairs and dodging obstacles at around 1.4 m/s, with ongoing refinements enhancing its fluidity.

- Manipulation and Sensing: G1’s force-controlled hands, including optional three-fingered models with tactile sensors, excel at delicate interactions like handshakes, sorting small items, or assisting with light assembly, supported by its four-microphone array for voice commands. Atlas’s 28 actuated degrees of freedom enable powerful manipulation—lifting up to 11 kg, tossing objects with precision, or assembling parts—bolstered by stereo vision and LiDAR. Optimus leverages its 40 DoF for fine motor skills, folding laundry, watering plants, or serving drinks, with FSD-derived vision recognizing objects and adapting to user instructions in real-time.

- Real-World Applications: The G1 is a natural fit for educational settings, elder care (e.g., helping with mobility or medication reminders), and light industrial tasks like quality inspections. Atlas shines in search-and-rescue operations, heavy logistics, and automotive manufacturing, with 2025 pilots showing its efficacy in team-based construction. Optimus targets domestic assistance—unloading groceries, playing games with kids, or tending bars—while also supporting factory automation, with Tesla envisioning a workforce of millions by 2026.

These capabilities highlight a future where robots complement human efforts, enhancing efficiency and accessibility across diverse sectors.

Pros and Cons: Balancing Potential and Challenges

Each robot brings unique advantages, tempered by areas for growth, reflecting the iterative nature of technological development.

- Unitree G1 Pros: Its affordability at $16,000 opens doors for widespread adoption, with thousands shipped in 2025 alone. The ultra-portable, foldable design (down to 69x45x30 cm) suits labs and homes, while the EDU model’s customizability supports cutting-edge research. The robust AI ecosystem, powered by OTA updates, ensures rapid skill enhancement. Cons: The 2-hour battery life limits extended use, and the 2-3 kg payload capacity restricts heavy lifting. Its smaller size hampers high-reach tasks, and some functions remain in beta, with occasional glitches during complex operations.

- Boston Dynamics Atlas Pros: Atlas offers superior strength and dexterity, lifting up to 11 kg dynamically and performing Olympic-level gymnastics like backflips and spins. Its adaptability in unstructured environments, enhanced by 2025’s LBMs, makes it ideal for rescue and industrial settings. Proven in high-stakes demos, it collaborates effectively in teams. Cons: The estimated $500K+ price tag keeps it out of reach for most, and its 89 kg weight makes it less versatile for consumer use. Proprietary technology slows deployment, limiting commercial availability.

- Tesla Optimus Pros: Leveraging Tesla’s FSD AI, Optimus delivers advanced learning capabilities, with a scalable price under $30,000 promising widespread access. Its 40 DoF and 20 kg payload enable versatile tasks, from household chores to factory work, with a design aimed at millions by 2026. Cons: As a 2025 prototype, it retains some teleoperation reliance, faces heat management challenges with its servos, and requires further refinement for full autonomy, delaying its seamless integration.

These trade-offs underscore the ongoing evolution of robotics, with each model pushing boundaries while addressing practical limitations.

Future Impacts: Opportunities and Considerations for a Collaborative Tomorrow

The potential of G1, Atlas, and Optimus to transform society is vast, offering opportunities for growth while inviting thoughtful consideration. The Unitree G1 supports China’s booming $1.12 billion humanoid market by 2025, projected to claim over 50% of the global share, with sales up 125% year-over-year. It addresses labor shortages in aging populations through elder care—assisting with mobility, administering medications, or providing companionship—while boosting manufacturing efficiency with precise sorting and assembly. In disaster zones, its agility aids in delivering supplies or reconnaissance, enhancing safety for human responders.

Boston Dynamics’ Atlas, backed by Toyota Research Institute, promises significant industrial gains. Its 2025 pilots demonstrate 24/7 assembly line support, heavy logistics optimization, and search-and-rescue missions in rubble-strewn environments, reducing human risk. The robot’s ability to work in teams could revolutionize construction timelines, offering a glimpse of automated infrastructure development.

Tesla’s Optimus, with its ambitious production goals, brings domestic assistance to the forefront. Imagine a robot unloading groceries, folding laundry, or playing interactive games with children, freeing up time for creative pursuits. In factories, it supports repetitive tasks, with Tesla aiming for millions deployed by 2026, potentially reshaping global supply chains. Economically, these advancements could spur growth, shifting jobs from manual labor to oversight, innovation, and AI management roles.

However, considerations are essential. The rise of these robots may displace millions in service, retail, and logistics sectors, necessitating reskilling programs to mitigate unemployment and inequality. Ethical oversight is critical—ensuring AI systems prioritize safety and fairness, especially as Optimus learns from human behavior or G1 scales in unregulated markets. Large-scale deployment, particularly Optimus’s millions, raises questions about data privacy and potential misuse, such as surveillance or military applications. Drawing from Skynet’s fictional narrative, these concerns serve as a gentle reminder to guide development with care, fostering collaboration over domination.

By 2030, we might see hybrid models emerge, combining G1’s affordability, Atlas’s strength, and Optimus’s adaptability. For now, the G1 is perfect for budget-conscious researchers and educators, Atlas suits heavy-duty industrial needs, and Optimus offers a promising start for home and factory integration. The future is bright with possibilities—let’s shape it with wisdom and foresight. Subscribe to Cyberdyne Chronicles for more updates on this exciting robotic revolution

Leave a comment